Description

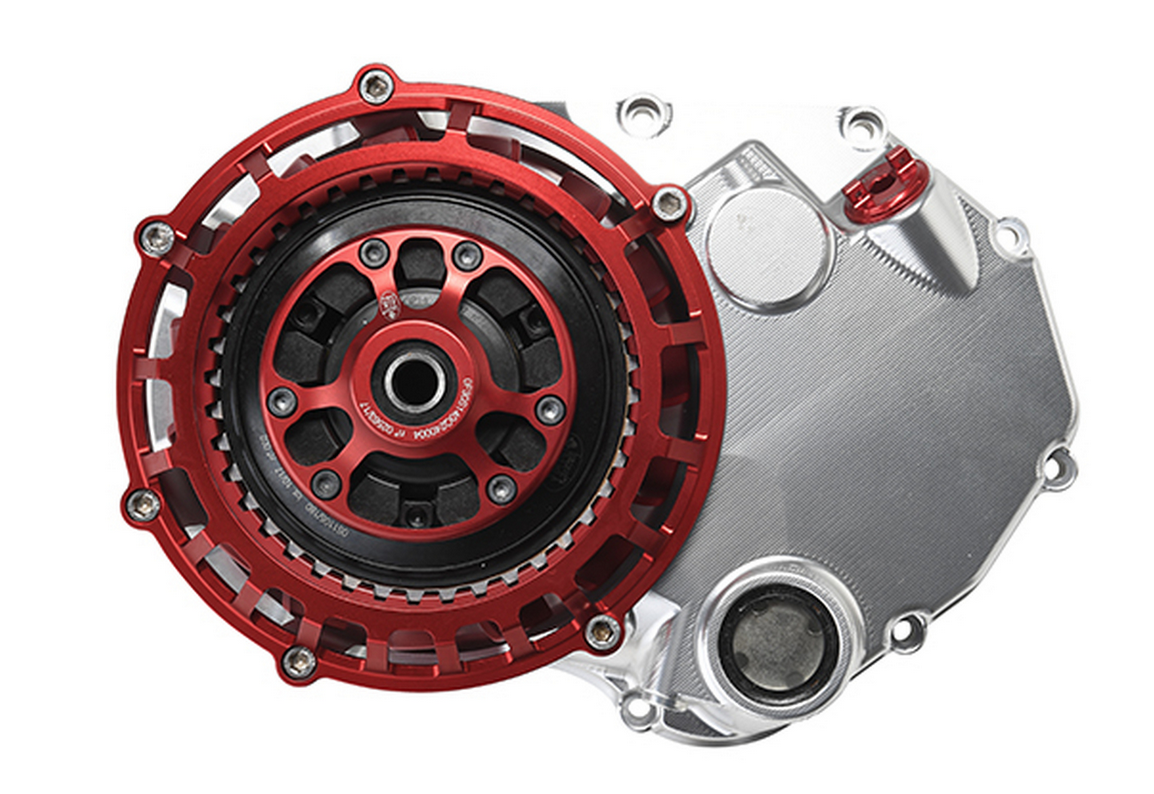

Besides sounding cool and looking like something out of Star Wars, the dry clutch conversion kit has added benefits:

1. Cleaner engine oil from no clutch disc contamination

2. No loss of power due to fluid drag- caused by clutch spinning in oil

3. STM EVO GP clutch runs cooler than other dry clutch systems

4. You get the classic Ducati look and sound

Includes:

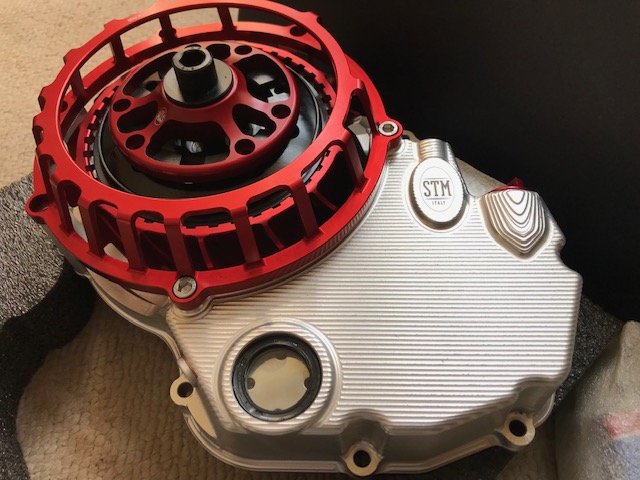

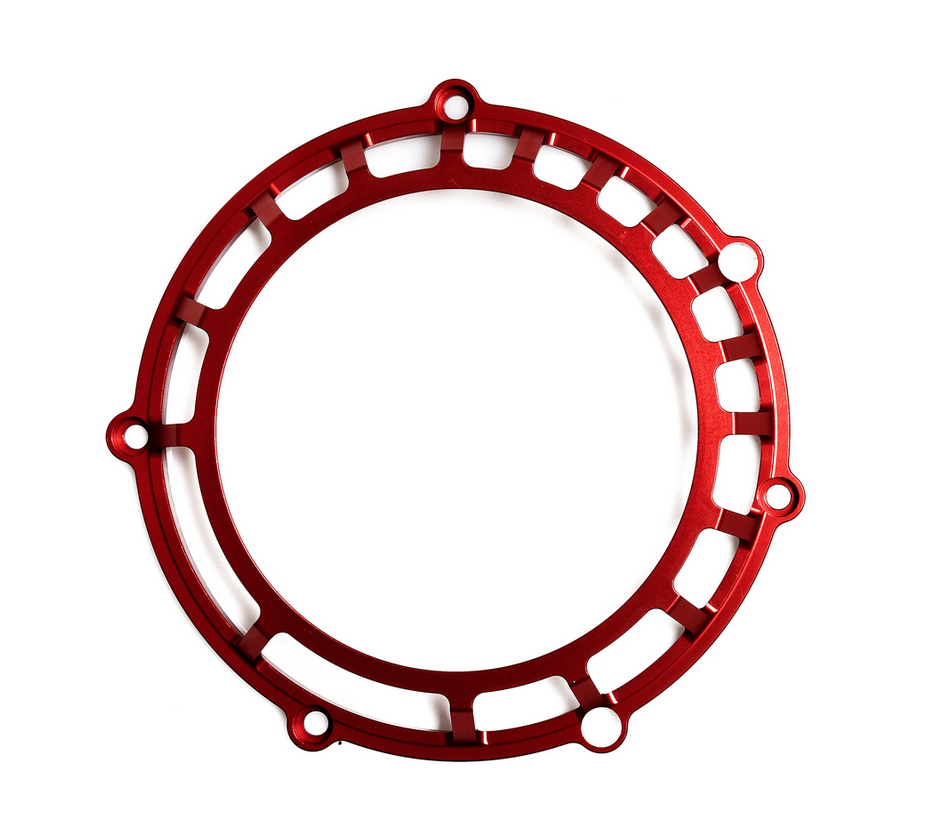

– Complete EVO-GP Slipper Clutch kit with basket and 40D disc clutch pack

– Replacement engine cover that is machined from billet aluminum

– Kit includes matching clutch cover

– 105 mm primary spring * Also available in differant weights 140 kg to 190 kg

– 60mm secondary spring * Also available in differant weights 40 kg to 80 kg

– Kit includes assembly instructions with disc pack diagram

EVO GP Details:

– The EVO GP Slipper Clutch is adjustable, by replacing primary and secondary springs the engine brake and clutch slip settings can be altered

– The EVO GP Slipper Clutch is small, lightweight and runs cool due to the clutch baskets spoon shaped outer fins. It is designed to move hot air away from the center of the clutch- improving overall performance.

– Built from hard steel alloy, the EVO GP is durable and doesn’t wear as fast as other slipper clutch designs.

– Each EVO GP Slipper Clutch come with suggested spring weights

– Utilizes STM specific 40 tooth clutch discs

***All STM slipper clutches for Ducati dry clutch motorcycles can be fitted with 12 and 48 tooth STM or OEM baskets, using STM or OEM disc packs.

Characteristics of STM EVO Slipper Clutches

There are 6 major components to a STM EVO Slipper Clutch: Hub, Drum, Pusher Plate, Spring Pusher and the Primary and Secondary Springs. Ball and ramp design allow the movement between the hub and inner drum > Secondary springs regulate amount of resistance to engine brake > Primary spring, pusher plate, spring pusher > Engage/disengage the clutch with the crankshaft input. The Ball and Ramp design allows the “slip” in the Slipper Clutch- reducing or eliminating wheel drag/rear wheel hop on down shift.

What is unique about the STM EVO slipper clutch?

Unlike other conventional coil spring slipper clutches the STM EVO clutch instead uses a primary and secondary diaphragm spring.

The Primary spring puts uniform pressure on the pusher plate and the clutch pack- acting as coil springs would. Primary springs are available in differant weights to match the characteristics (power) of the motorcycle engine. STM EVO clutch primary springs give consistant lever feel regardless of the wear condition of the clutch discs and a predictable, soft lever feel (if desired) compared to a conventional 6 helicoil spring setup.

The secondary spring controls the amount of pressure on the clutch drum and regulates the opening of the slipper clutch and amount of engine brake. Secondary spring.

– The STM EVO slipper clutch is adjustable, wherein the rider can adjust the amount of slip and engine braking- setting how much or how little the clutch slips is done by changing the weight of the secondary spring

– The lighter the secondary spring, the less engine brake there is.

– The heavier the secondary spring, the more engine brake there is.

– If a rider would like the feel of a 2-stroke engine for instance, then the lightest secondary spring possible would be used.

– The STM EVO slipper clutch primary and secondary springs have less drag than helicoil springs. This Diaphragm type spring is not under tension while the clutch is closed, unlike helicoil springs which are always slightly compressed.

– The STM EVO slipper clutch hub and drum are constructed of Steel Alloy- designed to be friction free with high wear resistance.

How a Slipper Clutch works:

~Without a slipper clutch

At speed- and on a sudden downshift and throttle closure, the motorcycles rear wheel abruptly slows, hopping or skidding as it meets back torque transmitted from the crankshaft. The rear wheel now wants to spin the engine, vice the engine spinning the rear wheel. This is caused by the engine revs suddenly increasing- due to a shorter gear being suddenly mismatched with the engine speed. This generates reverse torque (engine breaking)-putting energy from the crankshaft back into the clutch. With large displacement 4 stroke motors, more engine braking is generated- a 2-cyclinder Ducati 1198 as an example, can create a great deal of engine braking.

~With a slipper clutch

The reverse torque energy from the crankshaft is absorbed by the inner hub of the slipper clutch it’s connected to- Similar to a torque wrench, a slipper clutch will break at a specific level of force- that force resistance is broke by the hub lifting up and shifting on the balls and ramps of clutch drum-pushing the clutch pressure plate out. This disengages the clutch friction discs, ultimately freeing the rear wheel from the torque of the engine.

On the racetrack it allows you a safer and more efficient way to enter a corner while downshifting on the brakes all the way to the apex. Not having to worry about locking up the rear wheel in the brake zone is a major reason why riders choose a slipper clutch for the race track. With motorcycles that do not have electronic engine braking rider assistance, an STM EVO slipper clutch can also provide a level of tunability that cannot be acheived otherwise.

Benefits of the Slipper Clutch:

– Prevent engine overrev

– Reduced clutch lever pressure

– Better grip in the clutch pack on acceleration

– Assists the rear shock and chassis to remain stable on corner entry

– Prevents rear wheel lockup before and during corner entry, emergency braking/down shifting

– Can downshift without using the clutch lever (your clutch will last longer if you don’t do this)

– Enable the controlled sliding of your rear wheel (backing it in)

– Better clutch lever release from a stop light or starting grid- due to the diaphragm spring

– Preventing damage to your engine components and gearbox

– Mechanically assists and simulates feathering clutch manually- like required when riding without a Slipper Clutch

– Can enable faster lap time on the race track- enabling quicker down shifts and less to worry about in the brake zone.

__________________________________________________________________________________

Additional information

| Weight | 4 lbs |

|---|---|

| Dimensions | 18 × 12 × 8 in |

You must be logged in to post a review.

Reviews

There are no reviews yet.